The R&D+i Department is the most important at Mundimould. The job of analysis and research before manufacturing a mould is absolutely necessary in order to achieve the best final products.

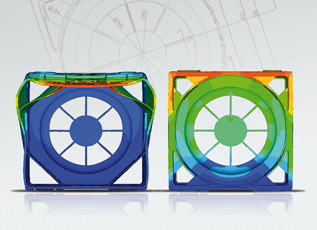

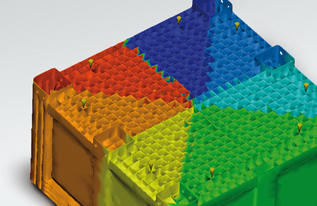

Structural analysis, savings in production costs, extension of the average life of the product, Modflow analysis, error prevention, resistance testing for heat, cold, and weight. To carry out this analysis in Mundimould we use the latest technology the most suitable computer software.

- CAD/CAM technology (Computer Assisted Design & Computer Assisted Manufacturing), with Pro-engineer software for automated solid modeling with learning software.

- CAE Technology (Computer Assisted Engineering), for realizing Moldflow analysis, structural, cinematic and collision analysis.

- CAF Technology (Computer Assisted Flow), for the flow analysis of the manufacturing process and the optimizing of production times.

- TER technology, to identify the areas with temperature problems.

- Information Management: system developed with personalized user name and password to achieve secure communication with the client, who can check at all times the progress of their project.

Another activity undertaken by our R&D+i department is the improvement of already completed moulds and products. The client sends us boxes or moulds which they wish to perfect and at Mundimould we carry out all the necessary analysis and tests to improve resistance, reduce the weight of the injectable product, reduce production costs etc....

As well as our research work, we also collaborate with technological Institutions and international companies in order to improve projects, moulds, and processes.

Video 1

Video 2